- Home

- MANUFACTURING PROCESS

MANUFACTURING PROCESS

HERE ARE THE CHARACTERISTIC PROCESS FOR EACH PRODUCTION STEP

01

DEVELOPMENT AND DESIGN

- Understanding customer needs and product specifications.

- Perform product design and engineering analysis.

- Create design drawings.

- Confirm and discuss with the customer, make modifications and adjustments.

- Finalize the design and proceed to the next stage of production.

02

LASER CUTTING

- Preparation for process conversion.

- Analyze heat-affected and burr-generating areas.

- Convert design drawings to program control for cutting.

- Verify details after forming.

03

EDGE DEBURRING

- Remove burrs generated during the cutting process.

- Ensure smooth and safe edges of the finished product without sharp corners.

- Perform surface treatment to enhance durability and aesthetics.

04

DRILLING / TAPPING / CHAMFERING

- Utilize precision drilling equipment for accurate hole positioning.

- Perform tapping operations according to specifications and design requirements.

- Perform chamfering to prevent sharp edges and corners.

05

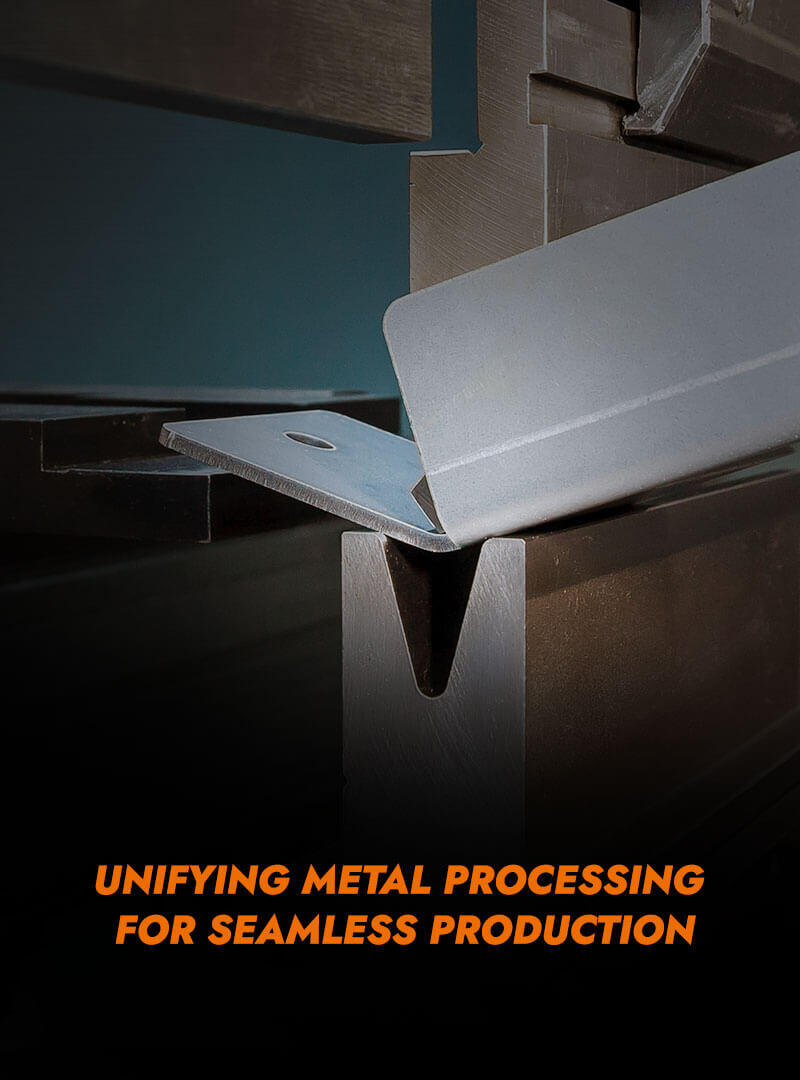

BENDING AND FORMING

- Perform pre-analysis prior to bending operations based on design requirements and specifications.

- Utilize precision press brake equipment with tooling to perform bending and forming of sheet metal.

- Achieve the desired angles and shapes.

- Utilize fixtures to prevent deformation and ensure consistency of the finished products.

06

SELF-INSPECTION

- Perform self-inspection during the process to ensure product quality.

- Utilize inspection instruments and tools for dimensional and specification checks.

- Conduct visual inspections to ensure integrity of the appearance.

- Record inspection results and make necessary adjustments and corrections.

07

WELDING ASSEMBLY

- Perform pre-confirmation of welding positions, deformation levels, and welding requirements.

- Carry out high-quality assembly welding operations based on welding processes.

- Ensure the strength of welds and the durability of welded products.

08

AUTOMATED WELDING ASSEMBLY

- Utilize robotic welding equipment for component welding assembly operations.

- Enhance production efficiency and consistency.

- Reduce human errors and operational risks.

- Ensure high precision and high-quality welding results.

09

QUALITY INSPECTION

- Conduct comprehensive quality inspections to ensure products meet specifications and quality standards.

- Utilize specialized inspection equipment and measurement tools for various tests.

- Test mechanical performance, durability, and other key characteristics.

- Inspect consistency and quality of welding, bending, and other processes.

10

CLEANING AND PACKAGING

- Perform cleaning to remove residues and contaminants after the production process.

- Utilize appropriate packaging materials and methods to ensure product protection and safety.

- Label and identify products accurately for easy identification of specifications.

- Ensure cleanliness and integrity before shipping.

11

SHIPPING

- Arrange shipping and logistics transportation to ensure timely delivery.

- Select suitable transportation methods and packaging techniques.

- Track the shipping status and provide accurate logistics information.

- Assist customers with customs clearance and documentation procedures to ensure smooth customs procedures and delivery.