ABOUT US

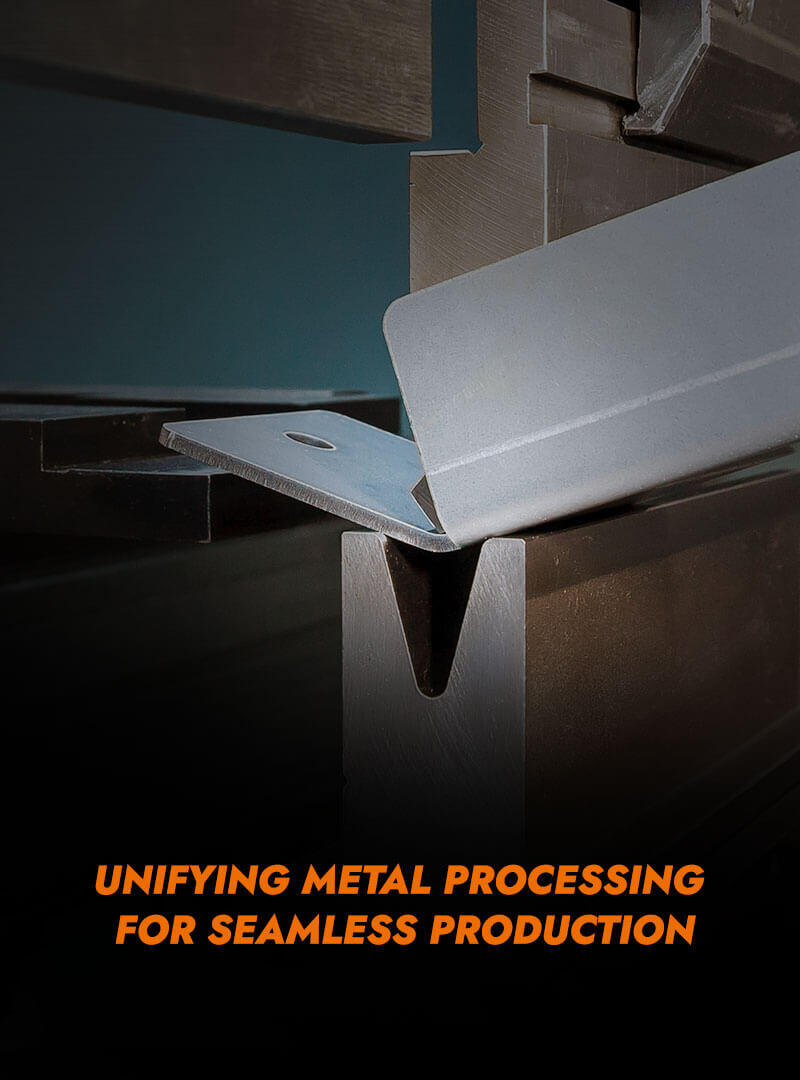

Established in 2004, Getyang Industrial specializes in the manufacturing of precision sheet metal products. We offer a comprehensive range of sheet metal manufacturing services, including initial design and development, laser cutting, welding, and assembly. To meet diverse service demands, we have also introduced large-scale laser tube cutting equipment, providing capabilities for equipment frame manufacturing and pipe cutting services.

Getyang Industrial integrates all metal processing steps for sheet metal products, including design, laser cutting, bending, tapping, welding, and subsequent surface treatments and assembly. This enables our customers to experience a full-service process from design and production to delivery and after-sales maintenance.

We are committed to upholding the core values of "fairness," "reasonableness," and "integrity," while adhering to a customer-oriented business philosophy. Our dedication lies in providing our customers with the highest value products, continuously improving our equipment, technology, and management processes. Our goal is to foster a mutually beneficial partnership, creating optimal success for both our customers and Getyang.

GET YANG

ADVANTAGE SERVICE

Laser Cutting

Design and Manufacturing of Various Machinery Bases

Optoelectronic Equipment Frames

Mold Development

ENTERPRISE HISTORY

Getyang Industrial: A journey of Continuous Excellence and Brand Value Creation

We are extend our deepest gratitude to the partners and customers who have supported Getyang Industrial throughout our journey. Thanks to your trust, we have continued to grow and enhance our capabilities. We look forward to creating more win-win opportunities together.

Getyang Industrial:

A Journey of Continuous Excellence & Brand Value Creation

We extend our deepest gratitude to the partners and customers who have supported Getyang Industrial throughout our journey. Thanks to your trust, we have continued to grow and enhance our capabilities. We look forward to creating more win-win opportunities together.

2004

- Established Getyang Industrial Co., Ltd.

- Offered customized laser cutting and welding product fabrication services.

2006

- Expanded operations with a new mechanical sheet metal plant.

- Integrated laser cutting, welding, and mechanical sheet metal expertise to provide a one-stop service for sheet metal product design and production management.

2011

- Acquired a Japanese OTC robotic welding arm, improving the quality of mass-produced welded products.

- Implemented 3D modeling software and techniques, enabling both 2D and 3D drawing applications.

- Introduced an ERP management system to enhance material and process management mechanisms.

2016

- Achieved ISO 9001:2015 certification from TÜV Rheinland.

- Improved and standardized operational processes across all departments.

2017

- Participated in the 2017 Taiwan International Laser Show and won 2nd place in the Craftsmanship Competition (Social Group).

- Enhanced process planning and adjusted factory safety protocols.

2018

- Joined the Semiconductor Association and participated in international semiconductor exhibitions.

- Drafted a plan for new factory expansion.

- Won the 14th Golden Hand Award (Potential Group).

2019

- Purchased 3,000 square meters of land.

- Planned the layout for the new factory, including land and equipment allocation.

2020

- Broke ground for the new factory.

- Prepared the old factory for relocation.

2022

- Acquired a Swiss Bystronic ByStar Fiber 4020 6KW laser cutting machine.

- Integrated BySoft CAM laser nesting software.

2023

- Completed construction of the new factory, now fully operational.

- Received Taiwan Patent Certificate No. M650172 for the improved structure of a filtration device, with the patented product commercialized.

2024

- Purchased an AMADA EGB 1303e Eco-friendly Electric Bending Machine from Japan.

- Secured Taiwan Patent Certificate No. M647592 for a multifunctional mobile workbench, currently undergoing in-factory mass production testing.

- Conducted a greenhouse gas emissions inventory audit, with guidance from the Environmental Sustainability and Reuse Service Center at Chaoyang University of Technology.

- Acquired the Italian BLM ADIGE LT8.20 laser tube cutting machine (tube material laser cutting equipment).

Through these milestones, Getyang Industrial continues to innovate, pushing the boundaries of excellence and environmental sustainability.

CERTIFICATE

Commitment to Environmental Sustainability

In addition to its industry-leading production capabilities, Getyang Industrial is deeply committed to environmental sustainability. Demonstrating its dedication to green energy, the company has installed solar panels on the rooftops of its factories. This investment in renewable energy not only reduces the company’s carbon footprint but also reflects Getyang’s long-term vision of contributing to a more sustainable future. By integrating eco-friendly practices into its operations, Getyang ensures that its growth and success are aligned with the principles of environmental stewardship.